Steam Traction : Development (North America)

A 1905 Best steam tractor (manufactured in California).The first steam tractors that were designed specifically for agricultural uses were portable engines built on skids or on wheels and transported to the work area using horses. Later models used the power of the steam engine itself to power a drive train to move the machine and were first known as "traction drive" engines[citation needed] which eventually was shortened to "tractor".[citation needed] These drive mechanisms were one of three types: chain, shaft, and open pinion. The open pinion became the most popular design due to its strength. Later improvements included power steering, differentials, compounded engines, and butt-strap boiler design.

The steam engine was gradually phased out by the mid-1920s as the less expensive, lighter, and faster-starting internal combustion (kerosene, petrol or distillate) tractors fully emerged after World War I.

Uses

Threshing

The drive belt: used to transfer power from a portable engine to a threshing machineThese engines were used extensively in rural North America to aid in threshing, in which the owner/operator of a threshing machine or threshing rig would travel from farmstead to farmstead threshing grain. Oats were a common item to be threshed, but wheat and other grains were common as well. On a "threshing day", all the neighbors would gather at that day's farmstead to complete a massive job in one day through cooperation. The women and older girls were in charge of cooking the noon meal and bringing water to the men. The children had various jobs based upon their age and sex. These jobs included driving the bundle racks, pitching bundles into the threshing machine, supplying water for the steam engine, hauling away the freshly threshed grain and scooping it into the granary. Steam traction engines were often too expensive for a single farmer to purchase, so "threshing rings" were often formed. In a threshing ring, multiple farmers pooled their resources to purchase a steam engine. They also chose one person among them to go to a steam school, to learn how to run the engine properly. There were also threshing contractors, who owned their own engine and thresher, and went to different farms, hiring themselves out to thresh grain.

Ploughing

The immense pulling power of steam tractors allowed them to be used for ploughing as well. Certain steam tractors were better suited for ploughing than others, with the large Minneapolis Threshing machine Co., J.I. Case, Reeves Co and Advance-Rumely engines being prime examples. Some of the largest steam tractors, such as the 150 horsepower (110 kW) Case (known as "Road Locomotives"), were capable of pulling 30 or more plough bottoms, while most were powerful enough to pull between 6 and 20. Differing soil conditions highly affected the ploughing abilities of these tractors.

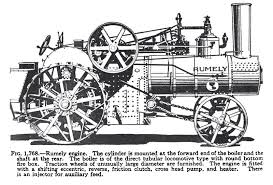

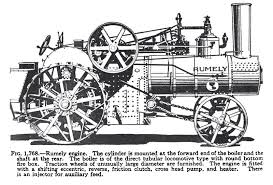

Rumely OilPull model HThe Advance-Rumely Company of La Porte, Indiana was organized in 1915 as a producer of many types of agricultural machinery, most notably threshing machines and large tractors. Advance-Rumely was purchased by Allis-Chalmers Manufacturing Company in 1931, and the company's main works would become what was later known as the "La Porte plant".

Thanks to various mergers and acquisitions, the company's origins stretched as far back as 1836. However, the origin of the two components of the corporate name—Advance Thresher Company and M. Rumely Company—were somewhat newer, though still long-lived in the agricultural equipment industry.